How Curtain Rings Work: A Comprehensive Guide

Curtain rings are a seemingly simple but fundamentally important element in window treatment design. They facilitate the smooth and efficient operation of curtains, allowing for easy opening and closing while also contributing to the overall aesthetic appeal. Understanding the mechanics and variations of curtain rings can greatly assist in selecting the appropriate type for specific curtain and rod configurations, ensuring optimal performance and longevity.

The basic function of a curtain ring is to suspend a curtain from a curtain rod. This allows the curtain to move horizontally along the rod, providing control over light and privacy within a room. The design of a curtain ring accommodates both the curtain itself and the rod, enabling a seamless connection between the two. Different types of rings cater to different curtain styles, rod diameters, and weight capacities.

The effectiveness of curtain rings hinges on several factors, including the material used, the method of attachment to the curtain, and the smoothness of the ring's inner surface. Friction between the ring and the rod is a critical consideration, as excessive friction can impede movement and place undue stress on the curtain fabric. Therefore, the selection of appropriate rings is not merely an aesthetic choice but also a practical one that affects the functionality and lifespan of the entire curtain system.

The Anatomy of a Curtain Ring

Curtain rings, despite their relatively simple appearance, consist of several key components that contribute to their overall functionality. A typical curtain ring comprises a circular or semi-circular body, a mechanism for attaching to the curtain, and, in some cases, an inner lining designed to reduce friction.

The ring body itself is usually made of metal, plastic, or wood. Metal rings are generally the most durable and can support heavier curtains. Plastic rings are lighter and more cost-effective but may be less durable. Wooden rings offer a more traditional aesthetic and are often used with heavier, more ornate curtains. The diameter of the ring must be appropriately sized to accommodate the curtain rod; a ring that is too small will not fit, while a ring that is too large may lead to instability and sagging.

The attachment mechanism is the component responsible for securing the curtain to the ring. This mechanism can take several forms, each with its own advantages and disadvantages. Common types include:

- Clips: These rings have small metal clips attached to the bottom, which grip the top edge of the curtain. Clips are easy to use and allow for quick attachment and removal. However, they can sometimes damage delicate fabrics.

- Hooks: These rings feature small hooks, typically made of metal, which are inserted into the heading tape of the curtain. Hooks provide a more secure attachment than clips and are less likely to damage the fabric. However, the curtain must have a suitable heading tape to accommodate the hooks.

- Sewn-on Rings: In this method, the rings are sewn directly onto the curtain fabric. This provides the most secure attachment but is also the most labor-intensive. Sewn-on rings are often used for custom-made curtains or those that require a very specific aesthetic.

- Eyelets: Eyelets are metal rings that are permanently installed within the curtain fabric. The curtain ring then passes through the eyelet. This ensures that the curtain is less likely to tear or fall off the rings.

Some curtain rings also include an inner lining, typically made of felt, plastic, or rubber. This lining serves to reduce friction between the ring and the rod, allowing the curtain to move more smoothly and quietly. The lining also helps to protect the rod from scratches and wear. Rings with linings are particularly useful for heavier curtains or those that are frequently opened and closed.

The Mechanics of Movement and Support

The core principle behind how curtain rings work is the distribution of weight and the minimization of friction. The rings evenly distribute the weight of the curtain along the length of the rod, preventing sagging and ensuring a uniform appearance. The smoothness of the ring's inner surface and the material of the rod are crucial factors in reducing friction and enabling smooth movement.

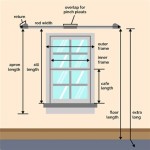

When a curtain is hung using rings, the weight of the fabric is transferred from the curtain to the rings and then from the rings to the rod. The number of rings used is directly related to the weight of the curtain; heavier curtains require more rings to adequately distribute the weight and prevent undue stress on individual rings and the rod itself. Generally, rings are spaced evenly along the top of the curtain to ensure uniform weight distribution.

Friction is a significant factor that can affect the ease of movement. High friction can make it difficult to open and close the curtains, while also potentially damaging the curtain fabric and the rod. The material of the rings and the rod, as well as the presence of any coatings or linings, can all influence the level of friction. Metal-on-metal contact, for example, typically generates more friction than metal-on-plastic or metal-on-felt. Similarly, a rough or corroded rod surface will increase friction compared to a smooth, polished surface.

The shape of the ring also plays a role in the mechanics of movement. Rings with a rounded inner surface tend to glide more smoothly along the rod than those with a square or angular shape. Some rings are designed with a slight curvature or an additional roller mechanism to further reduce friction. These specialized rings are often used for heavier curtains or in situations where smooth, effortless movement is particularly important.

Material Choices and Their Implications

The material of the curtain rings significantly impacts their durability, appearance, and performance. The most common materials used for curtain rings are metal, plastic, and wood, each offering unique advantages and disadvantages.

Metal rings are typically made of iron, steel, brass, or aluminum. They are known for their strength and durability, making them suitable for supporting heavy curtains. Metal rings can also be finished with various coatings, such as paint, lacquer, or plating, to enhance their appearance and protect them from corrosion. Brass rings offer a classic, elegant look and are resistant to rust. Steel rings are strong and relatively inexpensive but may be susceptible to rust if not properly coated. Aluminum rings are lightweight and corrosion-resistant, making them a good choice for humid environments.

Plastic rings are typically made of PVC or other synthetic materials. They are lightweight, inexpensive, and resistant to moisture. Plastic rings are available in a wide range of colors and styles, making them a versatile option for various decor schemes. However, plastic rings are generally less durable than metal rings and may not be suitable for supporting heavy curtains. They can also become brittle and crack over time, especially when exposed to sunlight or extreme temperatures.

Wooden rings are typically made of hardwood, such as oak, maple, or walnut. They offer a traditional, natural aesthetic and can be stained or painted to match the curtain fabric or the surrounding decor. Wooden rings are generally more expensive than metal or plastic rings and require more maintenance to prevent warping or cracking. They are often used with heavier, more ornate curtains to complement a traditional or rustic design style.

The choice of material should be based on several factors, including the weight of the curtains, the desired aesthetic, the budget, and the environmental conditions. For heavy curtains, metal rings are generally the best choice due to their strength and durability. For lighter curtains, plastic or wooden rings may be sufficient. The aesthetic should be considered to ensure that the rings complement the curtains and the overall room design. The budget is also an important factor, as metal rings are typically more expensive than plastic or wooden rings. Finally, the environmental conditions should be considered, especially in humid or coastal areas where corrosion-resistant materials are preferred.

Troubleshooting Common Issues

Even with properly selected and installed curtain rings, certain issues may arise that can impede smooth operation. Common problems include stiff or noisy movement, slipping or sagging, and damage to the curtain fabric or rod.

Stiff or noisy movement is often caused by friction between the rings and the rod. This can be due to a buildup of dust or dirt on the rod, corrosion of the metal, or dryness of the ring's inner surface. To resolve this issue, the rod should be cleaned regularly with a damp cloth and a mild detergent. For metal rods, a lubricant such as silicone spray can be applied to reduce friction. Rings with linings should be checked to ensure that the lining is still intact and providing adequate lubrication. If the rings are excessively worn or damaged, they should be replaced, and the curtain rod assessed for any damage that may add to the friction.

Slipping or sagging can occur if the rings are too large for the rod or if the curtains are too heavy for the number of rings being used. To correct this, ensure that the rings are properly sized for the rod and that the spacing between the rings is adequate to distribute the weight of the curtain evenly. If the curtains are particularly heavy, additional rings may be needed to provide more support. In some cases, it may also be necessary to replace the rod with a sturdier one that can handle the weight of the curtains.

Damage to the curtain fabric or rod can result from using rings with sharp edges or abrasive surfaces. Clips, in particular, can sometimes damage delicate fabrics if they are too tight or if they have sharp edges. To prevent this, use rings with smooth, rounded edges and avoid over-tightening clips. The rod should also be inspected regularly for any signs of damage or corrosion that could snag or tear the curtain fabric. Any rough spots on the rod should be smoothed down or covered with a protective coating.

Proper maintenance and timely replacement of worn or damaged rings can prevent many of these issues. Regular cleaning and lubrication can also extend the lifespan of the rings and ensure smooth, trouble-free operation of the curtains.

How Do Drapery Rings Work Tips From A Workroom

How Do Drapery Rings Work Tips From A Workroom

How Do Drapery Rings Work Tips From A Workroom

Curtain Clips What S The Best Way To Hang Your Drapery

How Do Drapery Rings Work Tips From A Workroom

How To Hang Curtains Using Drapery Pins And Ring Clips Stay Home Style

How Do Drapery Rings Work Tips From A Workroom

How Do Eyelet Curtain Rings Work The Perfect Choice For Style Function And Durability 2025 Machine Snap Button Jingcheng

Curtain Clips What S The Best Way To Hang Your Drapery

How To Hang Curtains With Hooks Grand Little Place