Curtain Rods Without Middle Support: A Comprehensive Guide

Curtain rods serve a dual purpose within a living space. They are functional elements that facilitate the hanging and manipulation of curtains, and they contribute significantly to the overall aesthetic of a room. While many curtain rod designs incorporate a middle support bracket to enhance stability, particularly for wider windows or heavier draperies, a distinct category exists: curtain rods designed to function without such mid-span support. Understanding the characteristics, applications, and limitations of these support-free rods is crucial for informed decision-making when selecting window treatments.

The absence of a middle support presents both advantages and disadvantages. The clean, uninterrupted line of a rod spanning a window opening can create a more streamlined and minimalist visual effect, especially desirable in contemporary design schemes. However, this design choice necessitates careful consideration of factors such as rod material, diameter, mounting hardware, and the weight of the curtains to be hung. Failure to account for these elements can lead to sagging, instability, and ultimately, a compromised aesthetic and functional performance.

Key Point 1: Material Selection and its Impact on Load Capacity

The material from which a curtain rod is constructed plays a pivotal role in its ability to withstand the weight of curtains without the assistance of a middle support. Several materials are commonly used, each possessing unique strength and flexibility characteristics that directly influence the maximum span achievable without sagging.

Steel is a popular choice due to its inherent strength and rigidity. Steel rods, particularly those with a larger diameter, can effectively support heavier curtains across wider spans compared to other materials. The tensile strength of steel allows it to resist bending and deformation under load. However, steel is also heavier, which can place additional stress on the mounting hardware. Furthermore, steel is susceptible to corrosion if not properly treated or coated, especially in humid environments.

Aluminum offers a lighter-weight alternative to steel while still providing reasonable strength. Aluminum rods are generally more resistant to corrosion than steel, making them suitable for bathrooms or coastal areas. However, aluminum is less rigid than steel, meaning that it will deflect or bend more readily under the same load. For longer spans or heavier curtains, aluminum rods may require a larger diameter to maintain adequate stability.

Wood is a classic material option that adds warmth and character to a room. The strength of a wooden curtain rod depends on the type of wood used. Hardwoods like oak or maple are considerably stronger than softwoods like pine. Wooden rods are typically thicker than metal rods to compensate for their lower tensile strength. While wood can be aesthetically pleasing, it is also susceptible to moisture damage and warping, especially if not properly sealed or treated. The weight of wood compared to aluminum becomes a factor in mounting hardware requirements as well.

Plastic or composite materials are also available, often at a lower cost. While these materials are generally lightweight and resistant to corrosion, they typically lack the strength and rigidity required to support heavy curtains across extended spans without sagging. Plastic rods are best suited for lightweight curtains in shorter window openings.

When selecting a curtain rod material, the weight and type of curtains to be used must be carefully considered. Lightweight sheer curtains can be supported by thinner rods made of aluminum or even plastic, whereas heavier lined drapes or blackout curtains require a stronger material like steel or a dense hardwood. The specific weight limits for a given rod material and diameter should be obtained from the manufacturer to ensure safe and reliable performance.

Key Point 2: Diameter and Wall Mounting Considerations

The diameter of a curtain rod is a critical factor in determining its load-bearing capacity and resistance to bending. A larger diameter rod will generally be stronger and more resistant to sagging than a smaller diameter rod made of the same material. The diameter must be appropriately scaled to the width of the window and the weight of the curtains.

For lighter curtains and shorter spans, a rod diameter of 1 inch may suffice. However, for heavier curtains or spans exceeding 4 feet, a diameter of 1.5 inches or greater is generally recommended. The manufacturer's specifications should be consulted to determine the optimal rod diameter for a given application.

Wall mounting hardware is equally important as the rod itself. The brackets used to secure the rod to the wall must be robust and capable of supporting the combined weight of the rod and the curtains. The type of wall construction also influences the choice of mounting hardware.

For drywall construction, it is essential to use appropriate anchors that are rated for the anticipated load. Standard drywall anchors may not be sufficient for heavier curtains, especially if the rod is extended a significant distance from the wall. Toggle bolts or molly bolts provide a more secure attachment to drywall, distributing the load over a wider area. Ideally, mounting brackets should be secured directly to wall studs whenever possible, offering the strongest and most reliable support.

For plaster walls, special consideration must be given to the brittle nature of the material. Drilling into plaster can cause cracking or crumbling if not done carefully. Using a slow drill speed and appropriate drill bit can help minimize damage. Plaster anchors or toggle bolts are generally recommended for plaster walls.

For concrete or brick walls, masonry anchors are required. These anchors are designed to expand within the drilled hole, creating a secure and permanent connection. The size and type of masonry anchor should be selected based on the weight of the curtains and the thickness of the wall.

The placement of the mounting brackets is also crucial. Brackets should be positioned as close to the ends of the rod as possible to maximize support and minimize sagging. For wider windows, it may be necessary to use additional brackets, even in the absence of a middle support, to distribute the load more evenly. The distance between brackets should be determined based on the rod material, diameter, and the weight of the curtains. A general rule of thumb is to space brackets no more than 36 inches apart.

Key Point 3: Alternative Solutions and Considerations for Longer Spans

When dealing with particularly wide windows or heavy curtains, achieving adequate support without a middle bracket can be challenging. In such cases, alternative solutions and strategies may be necessary to ensure stability and prevent sagging.

One option is to use a thicker, heavier-duty curtain rod made of a stronger material like steel. Increasing the rod diameter can significantly improve its load-bearing capacity. However, extremely thick rods may be aesthetically unappealing in some settings.

Another approach is to use multiple curtain rods instead of a single long rod. This involves dividing the window opening into smaller sections, each with its own rod and set of curtains. This approach can reduce the span of each individual rod, making it easier to achieve adequate support. However, using multiple rods may not be suitable for all window treatments or design styles.

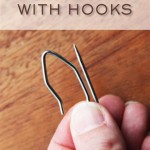

A less conventional solution involves using a cable or wire system instead of a traditional curtain rod. A strong cable or wire can be stretched across the window opening and secured to the walls with heavy-duty anchors. Curtains can then be hung from the cable using clips or rings. Cable systems can be very strong and unobtrusive, but they may not be suitable for all types of curtains or design styles.

Another consideration is the use of tiebacks or holdbacks. These accessories can be used to gather the curtains to the sides of the window, reducing the amount of weight that is pulling on the rod. Tiebacks can also enhance the aesthetic appeal of the window treatment.

Finally, it is important to remember that the type of curtains used can also affect the amount of stress placed on the curtain rod. Lightweight sheer curtains will exert less force than heavy lined drapes. Choosing lighter fabrics can help minimize the risk of sagging, especially when using rods without middle support.

In conclusion, selecting a curtain rod that functions without middle support requires a thoughtful evaluation of several interconnected factors. Material choice, rod diameter, mounting hardware, and the weight of the curtains are all critical considerations. By carefully assessing these elements and exploring alternative solutions when necessary, it is possible to achieve a visually appealing and functionally sound window treatment that meets the specific needs of the space.

How To Hide A Curtain Rod Center Support Bracket Exquisitely Unremarkable

No Drill Curtain Rod Brackets Kwik Hang

How To Hide A Curtain Rod Center Support Bracket Exquisitely Unremarkable

Bonnieprojects Extra Long And Curtain Rod

Ideas For Low Cost Curtain And Rod The Diy Girl

Curtain Rods From Galvanized Pipes Without The Look

How To Reinforce A Curtain Rod And Prevent Wall Damage

How To Hang Curtains Without Middle Support What Do When The Bracket Is Not An Option

How To Hide A Curtain Rod Center Support Bracket

5 Easy Ways To Hang Curtains Without Drilling

See Also