Best Double Curtain Rods For Heavy Curtains

Selecting the appropriate curtain rods is a critical aspect of interior design and functionality. This is especially true when dealing with heavy curtains, as the chosen rods must possess the requisite strength and stability to support the weight without bending, sagging, or, in the worst-case scenario, collapsing. Double curtain rods, designed to hold two layers of curtains, present an additional challenge, demanding even more robust construction. This article will explore the key considerations and features of double curtain rods best suited for supporting heavy curtains, providing valuable information for homeowners and designers alike.

The fundamental purpose of double curtain rods is to enable the layering of curtains. This allows for a greater degree of light control, privacy, and thermal insulation. The layer closest to the window often comprises sheer or light-filtering fabrics, providing daytime privacy while allowing natural light to permeate the room. The outer layer typically consists of heavier, more opaque fabrics designed to block light completely and provide enhanced insulation. The ability to manipulate these layers independently offers significant flexibility in creating the desired ambiance and mitigating energy loss.

However, the weight of heavy curtains, particularly thick blackout curtains or lined drapes, exerts considerable stress on the curtain rod system. Inferior rods, especially those constructed from lightweight materials like thin aluminum or plastic, are prone to bending and failure under such strain. Therefore, selecting double curtain rods engineered specifically to withstand substantial weight is paramount for both aesthetic appeal and structural integrity. The material of construction, the rod diameter, the bracket design, and the mounting hardware all play crucial roles in determining the weight-bearing capacity of the system.

Material and Construction: The Foundation of Strength

The material from which a double curtain rod is constructed is arguably the most important factor determining its ability to support heavy curtains. While aesthetics are a consideration, durability and strength should be prioritized. Several materials are commonly used in the manufacture of curtain rods, each with its own set of advantages and disadvantages.

Steel is generally considered the gold standard for heavy-duty curtain rods. Its inherent strength and resistance to bending make it ideal for supporting substantial weight. Steel rods can be found in various finishes, including brushed nickel, black, and bronze, allowing homeowners to coordinate with their existing decor. High-quality steel rods will undergo a surface treatment process, such as powder coating or plating, to prevent rust and corrosion, ensuring longevity.

Wrought iron offers similar strength characteristics to steel but often boasts a more decorative, rustic aesthetic. Wrought iron rods are typically hand-forged, adding a unique, artisanal touch to the window treatment. However, wrought iron can be heavier than steel, potentially requiring even more robust mounting hardware. Like steel, wrought iron requires a protective coating to prevent rusting, especially in humid environments.

Brass is another durable option, known for its resistance to corrosion and its elegant, timeless appearance. While brass is strong, it is generally not as strong as steel or wrought iron and tends to be more expensive. Solid brass rods are a premium choice, while brass-plated rods offer a more budget-friendly alternative. However, brass-plated rods may be less durable over time, as the plating can wear away, exposing the base metal underneath.

Aluminum, while lightweight and affordable, is generally not recommended for supporting heavy curtains. While certain aluminum alloys can be relatively strong, they typically lack the rigidity and resistance to bending required for demanding applications. Aluminum rods are better suited for lighter-weight curtains or sheer fabrics.

Ultimately, the choice of material depends on the specific weight of the curtains and the desired aesthetic. For truly heavy curtains, steel or wrought iron are the most reliable options. When selecting a material, it is essential to consider the thickness and diameter of the rod itself, in addition to the material composition.

Bracket Design and Placement: Distributing the Load

The brackets that support the curtain rods play a crucial role in distributing the weight of the curtains and preventing sagging. Brackets must be constructed from durable materials and securely mounted to the wall. Insufficient or poorly designed brackets can lead to rod failure, even if the rods themselves are made from strong materials.

Heavy-duty brackets are typically made from steel or wrought iron to ensure adequate strength. The design of the bracket should provide ample support for both rods, with minimal flex or wobble. Look for brackets with a wide base that distributes the weight evenly across the wall. Adjustable brackets offer flexibility in positioning the rods at the desired distance from the wall, allowing for proper drape and clearance.

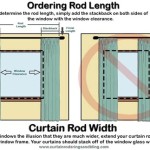

The number of brackets required depends on the length of the curtain rod and the weight of the curtains. As a general guideline, a bracket should be placed every 3 to 4 feet for heavy curtains. For particularly long rods, or when supporting very heavy fabrics, additional brackets may be necessary. It is crucial to distribute the brackets evenly along the rod to ensure uniform weight distribution.

Proper bracket placement is also essential. Brackets should be securely mounted to wall studs whenever possible. Wall studs provide the strongest and most reliable anchoring point. If wall studs are not accessible, heavy-duty drywall anchors should be used. Avoid using standard drywall anchors, as they are unlikely to provide sufficient support for heavy curtains. Toggle bolts are a good option for drywall applications, as they distribute the weight over a larger area, providing greater stability.

The distance from the wall at which the brackets are mounted also affects the weight-bearing capacity of the system. Mounting the brackets closer to the wall reduces the leverage force on the rod, making it less likely to bend or sag. Consider using adjustable brackets to fine-tune the distance and optimize the support.

Mounting Hardware and Installation: Ensuring a Secure Fit

Even the strongest curtain rods and brackets are rendered ineffective if the mounting hardware is inadequate or the installation is performed improperly. Selecting the correct screws, anchors, and other hardware is crucial for ensuring a secure and reliable installation.

When mounting brackets to wall studs, use long, sturdy screws that penetrate deep into the wood. Avoid using short screws, as they may not provide sufficient holding power. Screws with a coarse thread are generally preferred for wood applications, as they bite into the wood more effectively.

When mounting brackets to drywall, use heavy-duty drywall anchors designed to support significant weight. Toggle bolts are a particularly good choice, as they provide a strong and secure hold. Follow the manufacturer's instructions carefully when installing drywall anchors. It is essential to drill the correct size hole and to ensure that the anchor is properly seated in the wall.

For plaster walls, specialized plaster anchors are available. These anchors are designed to grip the plaster and provide a stable mounting point. It is important to select anchors that are specifically designed for plaster, as standard drywall anchors may not work effectively.

Before installing the brackets, carefully measure and mark the desired locations. Use a level to ensure that the brackets are aligned horizontally. An accurate installation is crucial for ensuring that the curtain rods hang straight and evenly.

After installing the brackets, test their stability by applying downward pressure. If the brackets wobble or feel loose, re-tighten the screws or replace the anchors. It is important to ensure that the brackets are securely mounted before hanging the curtains.

In addition to the mounting hardware, the installation technique also plays a crucial role. Avoid over-tightening the screws, as this can strip the threads or damage the wall. Use a manual screwdriver to avoid applying too much force. If using a power drill, set the torque to a low setting to prevent over-tightening.

When hanging the curtains, distribute the weight evenly across the rod. Avoid bunching the curtains up in one area, as this can create excessive stress on the rod. Use curtain rings or hooks that are appropriate for the weight of the curtains.

Regularly inspect the curtain rod system for any signs of loosening or damage. Tighten any loose screws or replace any worn-out hardware. With proper care and maintenance, a well-installed and appropriately chosen double curtain rod system can provide years of reliable service, even when supporting heavy curtains.

Best Heavy Duty Curtain Rods Review The Jerum Post

Tips For Ing A Double Curtain Rod Drapery Rods Direct

Double Curtain Rod Brackets And Rods Drapery Direct

Best Places To For Curtain Rods 2024

Wrought Iron Double Curtain Rods Made In Usa

Wrought Iron Double Curtain Rods Made In Usa

The Best Blackout Curtains Reviews By Wirecutter

Best Places To For Curtain Rods 2024

Umbra Cappa 66 In 120 Double Curtain Rod Black 1014401 111 The Home

9 Best Curtain Rods 2024 The Strategist