Light Curtain Laser Alignment Tool: Precision and Efficiency for Machinery Alignment

In the world of industrial machinery, precise alignment is paramount for optimal performance, reduced downtime, and prolonged equipment lifespan. Misaligned machinery can lead to a multitude of problems, including increased vibration, premature wear and tear, reduced efficiency, and even safety hazards. To address these challenges, manufacturers rely on sophisticated tools and techniques, among which the light curtain laser alignment tool stands out as a reliable and efficient solution.

A light curtain laser alignment tool utilizes the principles of laser technology to project a highly visible and precise beam of light, which acts as a reference line for aligning various components of a machine. These tools are versatile and can be used for a wide range of alignment tasks, including:

- Shaft alignment

- Gearbox alignment

- Bearing alignment

- Conveyor belt alignment

- Coupling alignment

- Machine foundation alignment

The use of a light curtain laser alignment tool offers numerous advantages over traditional alignment methods, such as using plumb bobs, spirit levels, and dial indicators. These advantages include:

Enhanced Accuracy and Precision

Light curtain laser alignment tools provide unmatched accuracy and precision, ensuring that components are aligned to the tightest tolerances. The laser beam acts as a highly visible and stable reference line, enabling technicians to achieve precise measurements and adjustments with minimal error. This level of accuracy is crucial for optimizing machine performance and preventing premature wear and tear.

Increased Efficiency and Time Savings

Traditional alignment methods often involve time-consuming procedures, requiring multiple measurements and adjustments. Light curtain laser alignment tools streamline the process, enabling technicians to quickly and accurately determine misalignment and make necessary adjustments. This efficiency translates into significant time savings and reduced downtime, allowing for quicker machine setup and resumption of production.

Improved Safety

Traditional alignment methods can pose safety risks to technicians, especially when working with heavy machinery or in confined spaces. Light curtain laser alignment tools eliminate the need for manual manipulation of components and reduce the risk of injury or accidents. The laser beam provides a clear visual reference, allowing technicians to work safely and efficiently.

Ease of Use and Versatility

Light curtain laser alignment tools are designed to be user-friendly and versatile. They are equipped with intuitive controls and clear displays, making them easy to operate by even novice technicians. These tools can be used for a wide range of alignment tasks, making them a valuable asset for any industrial facility.

Key Features of a Light Curtain Laser Alignment Tool

Light curtain laser alignment tools come equipped with a variety of features that contribute to their accuracy, efficiency, and ease of use. Some of the key features include:

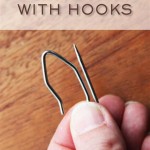

Laser Beam Technology

The core technology of a light curtain laser alignment tool is the laser beam itself. High-quality lasers produce a precise and stable beam that accurately reflects the target alignment. The beam can be projected over long distances, and its clarity and stability are not affected by ambient light conditions.

Laser Beam Adjustments

To ensure accurate alignment, light curtain laser alignment tools offer various adjustments for the laser beam. These adjustments include:

- Beam height adjustment: Allows for precise vertical alignment by adjusting the height of the laser beam.

- Beam angle adjustment: Enables fine-tuning of the beam's angle for accurate horizontal alignment.

- Beam focus adjustment: Allows for adjusting the beam's focus for optimal visibility and clarity.

Measurement Display

Light curtain laser alignment tools are often equipped with a digital display that shows accurate measurements of misalignment. These displays can show both horizontal and vertical deviations, enabling technicians to identify and correct any misalignment with precision.

Data Logging and Analysis

Some light curtain laser alignment tools offer data logging capabilities, allowing technicians to record alignment data for future analysis. This data can be used to track trends, identify potential issues, and optimize machine performance over time.

Types of Light Curtain Laser Alignment Tools

Light curtain laser alignment tools are available in various types, each designed for specific applications and requirements. Some common types include:

Single Beam Laser Alignment Tools

Single beam laser alignment tools project a single laser beam, making them suitable for basic alignment tasks that require a single reference line. These tools are typically more affordable and less complex to operate.

Dual Beam Laser Alignment Tools

Dual beam laser alignment tools project two parallel laser beams, providing a more comprehensive view of the alignment. These tools are often used for complex tasks that require precise alignment in both horizontal and vertical directions.

Multi-Beam Laser Alignment Tools

Multi-beam laser alignment tools project multiple laser beams, creating a "light curtain" that covers a wider area. These tools are ideal for aligning large and complex machinery where a single beam may not be sufficient for accurate alignment.

Selecting the right type of light curtain laser alignment tool depends on the specific application, the size and complexity of the machinery, and the required level of accuracy.

Conclusion

Light curtain laser alignment tools have revolutionized the process of machinery alignment, providing industrial facilities with enhanced accuracy, efficiency, and safety. By harnessing the power of laser technology, these tools enable technicians to achieve precise alignment with minimal effort and downtime, ultimately optimizing machine performance and prolonging equipment lifespan. As technology continues to advance, we can expect even more innovative and sophisticated light curtain laser alignment tools to emerge, further enhancing the efficiency and accuracy of machinery alignment in the years to come.

Lad 4 Laser Alignment Device For Safety Light Curtains Reer

Tapeswitch Corp Laser Alignment Tool

Laser Alignment Tool For Safety Light Curtains Z98g001 Wenglor

Lad 4 Laser Alignment Device For Safety Light Curtains Reer

Banner Engineering Lat 1 Sgs Sensor Hardware Accessories

Sick Ar60 Laser Alignment Aids 1015741 New Kd

Light Curtain Accessories 279 5 Contrinex Yxl 0001 000 Laser Alignment Tool Accessory 1 Mw Output Power 2 To 3 V Dc Voltage

Laser Alignment Aid

Lat 2 Banner Engineering Lt7 Alignment Tool

Laser Alignment Tool For Reer Micron Light Grids Pn Lad4 Automationdirect